In Singapore’s industrial hubs like Tuas or Jurong, pumps are the “heart” of the operation, but the motor is the “muscle” that makes them beat. Here is why you can’t have one without the other.

1. The Power Source (Kinetic Energy)

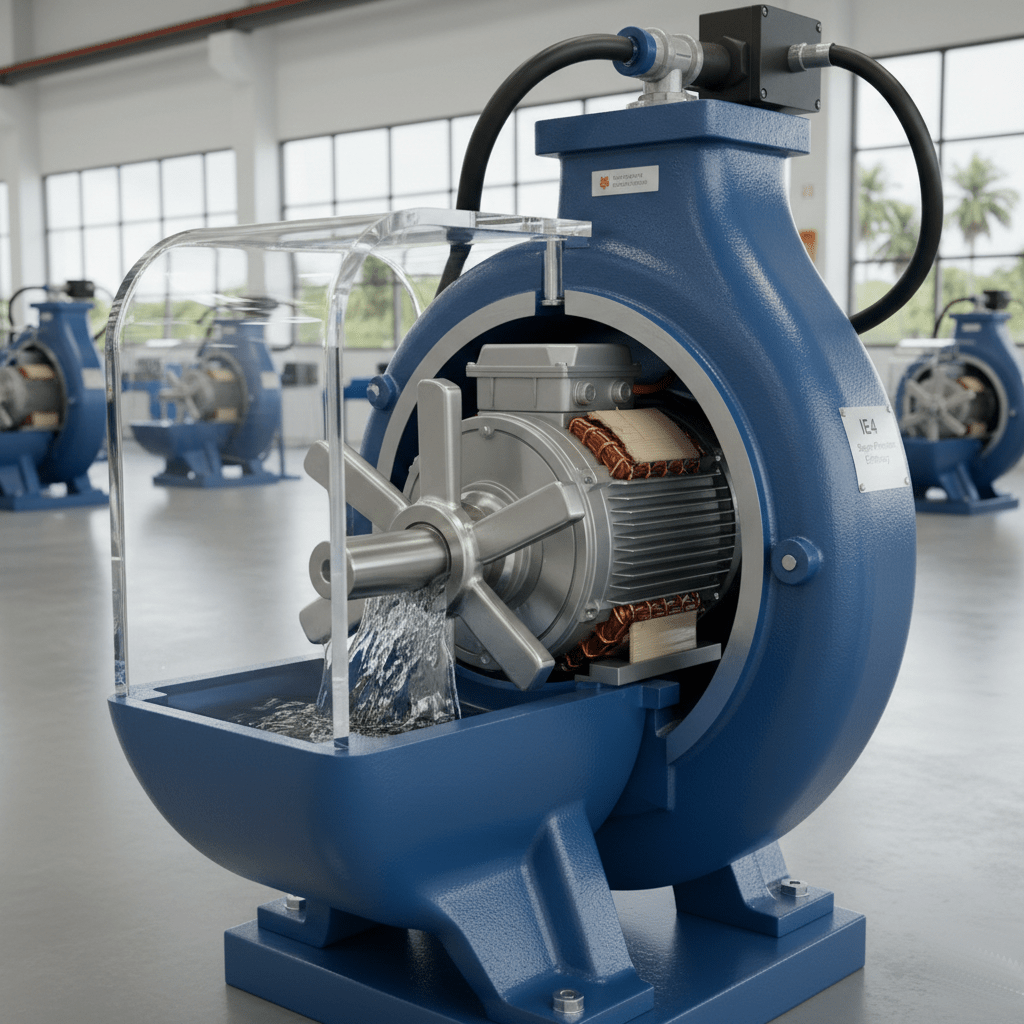

A pump is just a casing with an impeller inside; it cannot move on its own. The motor converts electrical energy from the grid into mechanical rotation. Without this torque, the fluid remains stationary.

2. Overcoming “Head” and Pressure

In Singapore’s high-rise buildings and deep drainage systems, water must be pushed against gravity. This is known as Total Dynamic Head. A motor provides the constant force required to overcome this resistance and maintain water pressure.

3. Precision Flow Control with VSDs

Modern Singaporean factories focus on energy efficiency. By pairing a pump with a Variable Speed Drive (VSD) motor, you can control the speed of the fluid.

- Why it matters: It prevents “Water Hammer” (pipe damage) and slashes electricity bills, helping companies meet NEA energy standards.

4. Continuous 24/7 Operation

Whether it’s a cooling tower for a Data Centre in Jurong or a NEWater treatment plant, pumps must run non-stop. Industrial motors (specifically IE3 or IE4 class) are engineered to provide this constant rotation without overheating in Singapore’s humid climate.

5. Automated System Integration

In the era of Industry 4.0, motors act as the bridge to automation. A motor can be linked to sensors that tell the pump when to start, stop, or slow down based on real-time demand, reducing the need for manual labor.