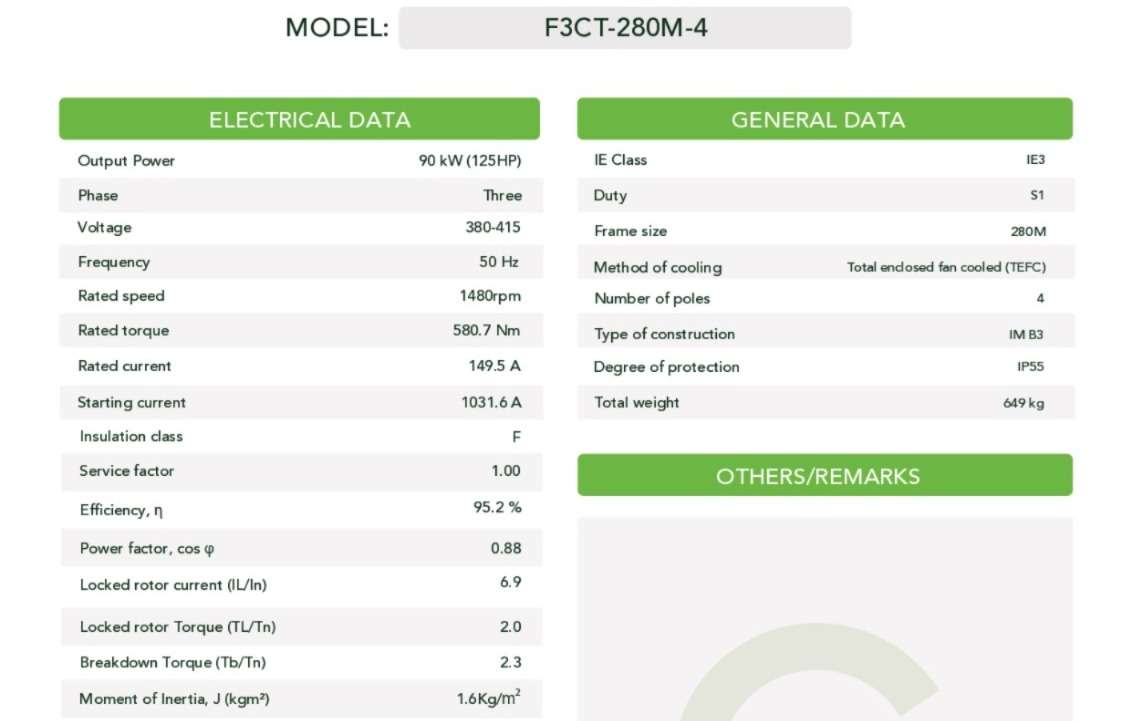

Understanding a motor datasheet is more than just reading numbers; it is about ensuring long-term reliability and operational cost-efficiency for your facility. Before requesting a quote, mastering these technical specifications allows you to communicate effectively with suppliers and select a motor that perfectly matches your mechanical requirements and electrical infrastructure. We use Greentec motor model F3CT-280M-4 as an example:

1. Primary Power Specs

These define if the motor fits your electrical system and load requirements.

- Output Power (90 kW / 125HP): The mechanical work the motor can perform.

- Voltage (380-415V) & Frequency (50 Hz): Must match your local power grid to avoid damage.

- Rated Speed (1480 rpm): The actual speed of the shaft under full load.

- Rated Torque (580.7 Nm): The rotational force the motor generates.

2. Efficiency & Performance

Critical for calculating long-term operating costs and reliability.

- IE Class (IE3): Indicates “Premium Efficiency”.

- Efficiency, (95.2%): The percentage of electrical energy converted into mechanical work.

- Power Factor, (0.88): How effectively the motor uses incoming current.

3. Physical & Protection Limits

Essential for installation and maintenance planning.

- Frame Size (280M): Standardized dimensions for mounting.

- Degree of Protection (IP55): Dust protected and resistant to water jets.

- Location: Due to the IP55 rating, this motor is suitable for indoor or sheltered outdoor environments.

- Duty (S1): Rated for “Continuous Duty,” meaning it can run 24/7.

- Method of Cooling (TEFC): Total Enclosed Fan Cooled design ensures the motor stays cool even in demanding applications.

4. Typical Applications

Given the high power output 90kW and IE3 efficiency rating, this motor is ideal for:

–Compressors: High-pressure air systems.

–Heavy-Duty Industrial Pumps: Water treatment or chemical processing.

–Large Ventilation Systems: Industrial fans and blowers.

–Conveyor Systems: Mining or manufacturing assembly lines.

By focusing on these core parameters—power, efficiency, and physical protection—you can ensure this motor is the right choice for your specific application. Reliable data like this is the backbone of efficient engineering and maintenance, helping you prevent costly downtime while maximizing the lifespan of your industrial equipment and energy savings.