The shift from DC motors to AC motors paired with Variable Frequency Drives (VFDs) is a strategic move driven by operational and financial benefits. This transition addresses the inherent maintenance challenges of older DC technology while capitalizing on the superior efficiency and ruggedness of modern AC systems.

DC vs. AC Motors: The Key Difference

| Aspect | Old System (DC Motor) | New System (AC Motor with VFD) | Why the Change? (AC Advantage) |

| Maintenance | High: Needs regular replacement of brushes/commutator. | Low: Brushless design means virtually no wear parts. | Saves Time & Money: Less downtime and fewer repairs. |

| Reliability | Lower: Prone to mechanical failure and overheating. | High: Rugged, simple, and built for continuous operation. | More Uptime: Equipment runs longer without breaking down. |

| Energy Use | Less efficient, especially at lower speeds. | Superior Efficiency: VFDs match power precisely to the load. | Saves Energy: Lower electricity bills and better for the environment. |

| Long-Term Cost | High: Maintenance and energy costs add up over time. | Lower Total Cost: Initial investment is offset by huge savings. | Better ROI: Higher profits from reduced operational expenses. |

Conclusion

The transition from DC to AC motors is primarily a strategic move to secure long-term operational savings and reliability. The fundamental advantage of the AC system is its brushless design, which eliminates the high-maintenance, wear-prone parts found in DC motors. This drastically reduces maintenance costs and dramatically increases uptime. Coupled with a Variable Frequency Drive (VFD), the AC system also delivers superior energy efficiency across all operating conditions. While the initial cost may be higher, the combined savings on maintenance and energy quickly make the AC motor system the most financially and logistically sound choice.

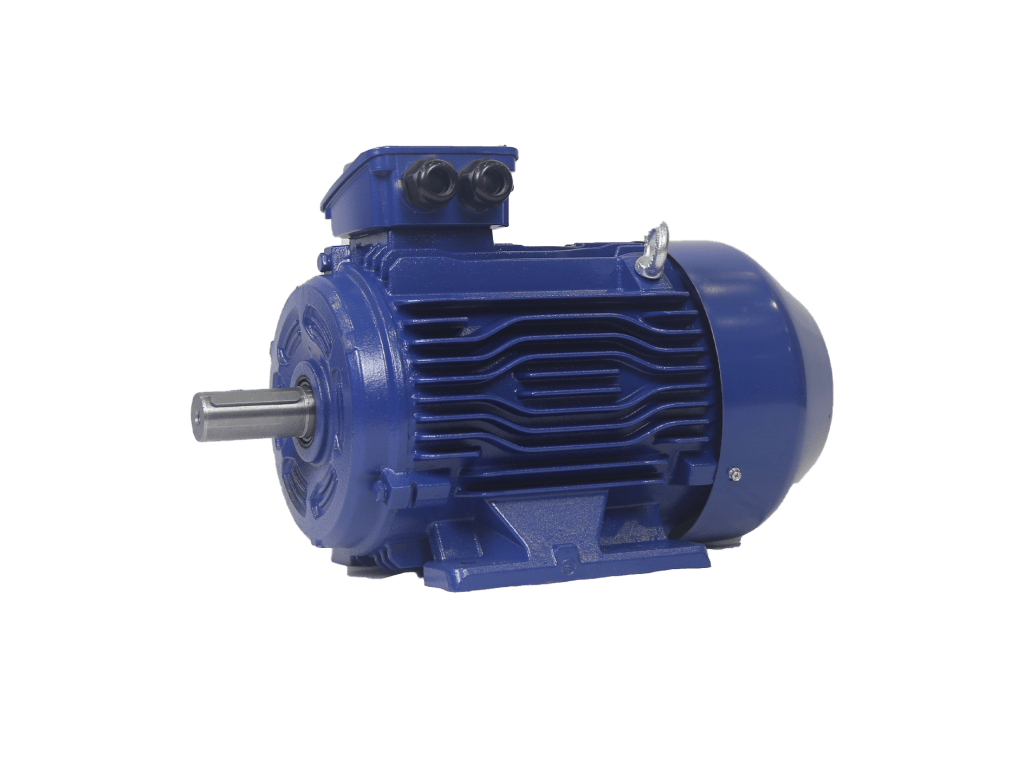

Contact us to choose your own Ac motor!