Description

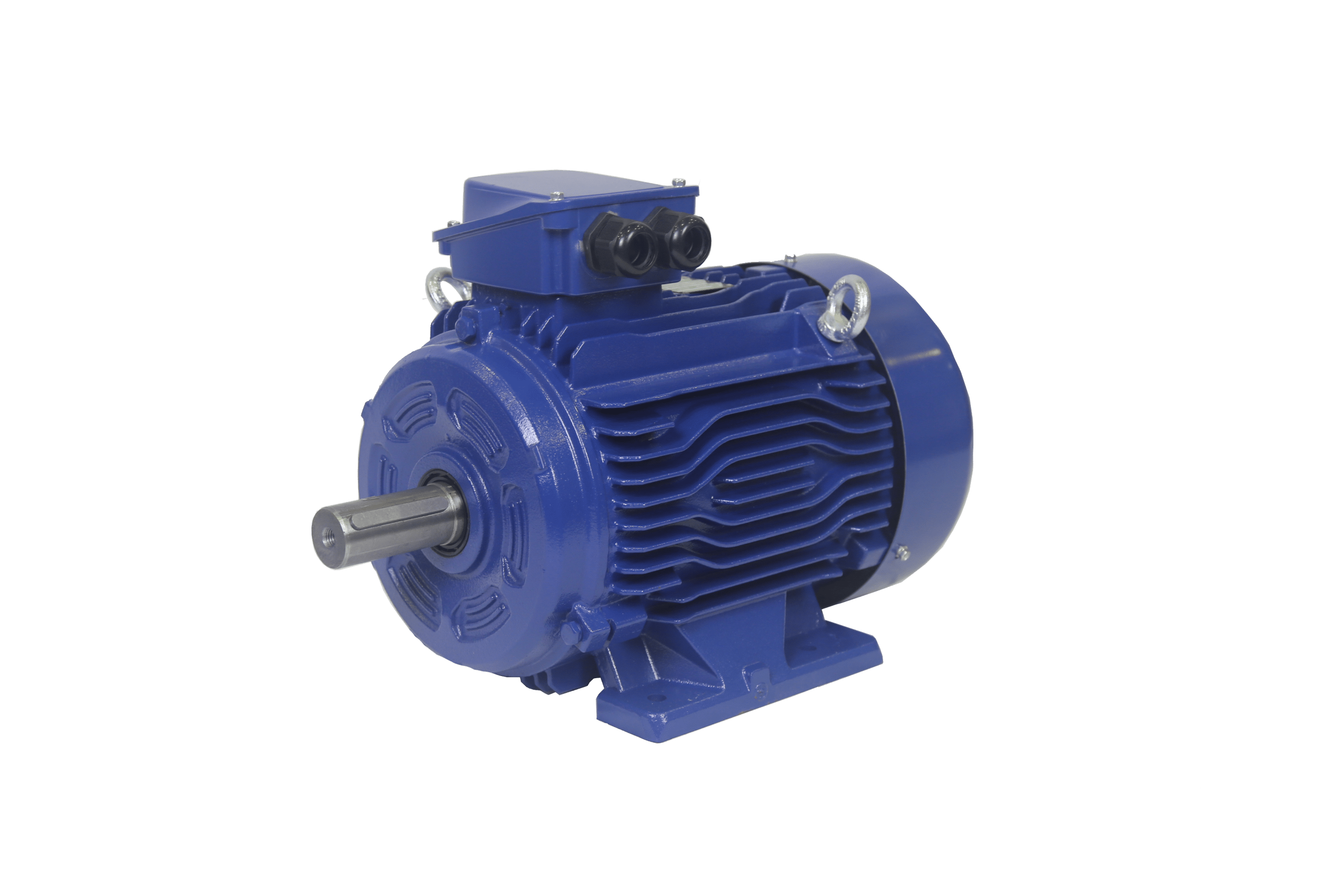

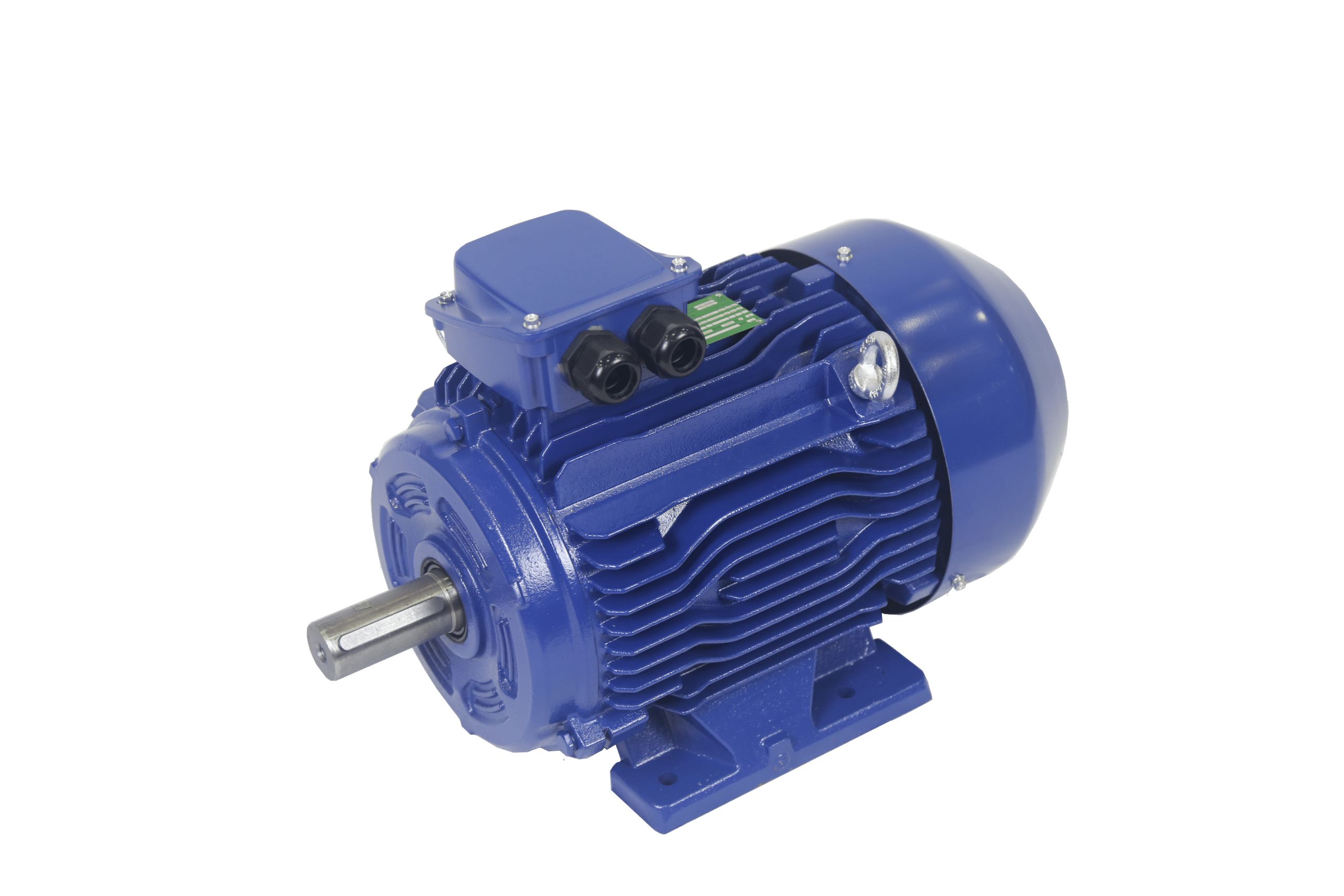

Induction Motors: The Workhorse of Industry

An induction motor (or ac motor) is the most common type of ac motor used today. It works by electromagnetic induction, generating current in the rotor without any physical connection. Known for their simple design, durability, and high energy efficiency, induction motors are essential for industrial, commercial, and household applications. The three-phase induction motor is preferred in industry for its higher power and stable performance.

Key Features and Benefits

- Simple and Rugged: Fewer moving parts mean less wear, tear, and a longer service life for this robust ac motor design.

- High Efficiency: Modern ac motors meet IE2 and IE3 standards, significantly cutting energy use and operational costs.

- Low Maintenance: No brushes or commutators simplify maintenance, making the induction motor perfect for continuous operation.

- Reliable Performance: Deliver consistent torque and speed control even under heavy loads.

- Cost-Effective: Affordable to purchase, install, and operate due to their efficiency and longevity.

Common Induction Motor Applications

Induction motors are versatile powerhouses across numerous industries. These reliable ac motors are found in:

- Fluid ManagementPumps, Compressors, Fans, Blowers, HVAC systems

- Material HandlingConveyor Systems, Production Lines

- ManufacturingMachine Tools (Lathes, Milling), Grinding Machines

- ResidentialWashing Machines, Refrigerators, Air Conditioners

How to Select the Right Induction Motor

Choosing the correct induction motor ensures optimal efficiency and performance. Consider these crucial factors when selecting your next ac motor:

- Power & Torque: Match the motor’s rating to the specific load requirements.

- Voltage & Frequency: Select the correct specifications (e.g., 220V/50Hz) for your electrical supply.

- Efficiency Rating: Prioritize IE3 for maximum long-term energy savings from your ac motor.

- Environmental Conditions: Check the IP protection class (e.g., IP55) to ensure suitability for the operating environment (dust, humidity, temperature).